|

Snowflake - In Win H-Frame 2.0 for Computex 2017 |

Post Reply

|

Page 12> |

| Author | |

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: Snowflake - In Win H-Frame 2.0 for Computex 2017 Topic: Snowflake - In Win H-Frame 2.0 for Computex 2017Posted: 03 Apr 2017 at 1:23am |

|

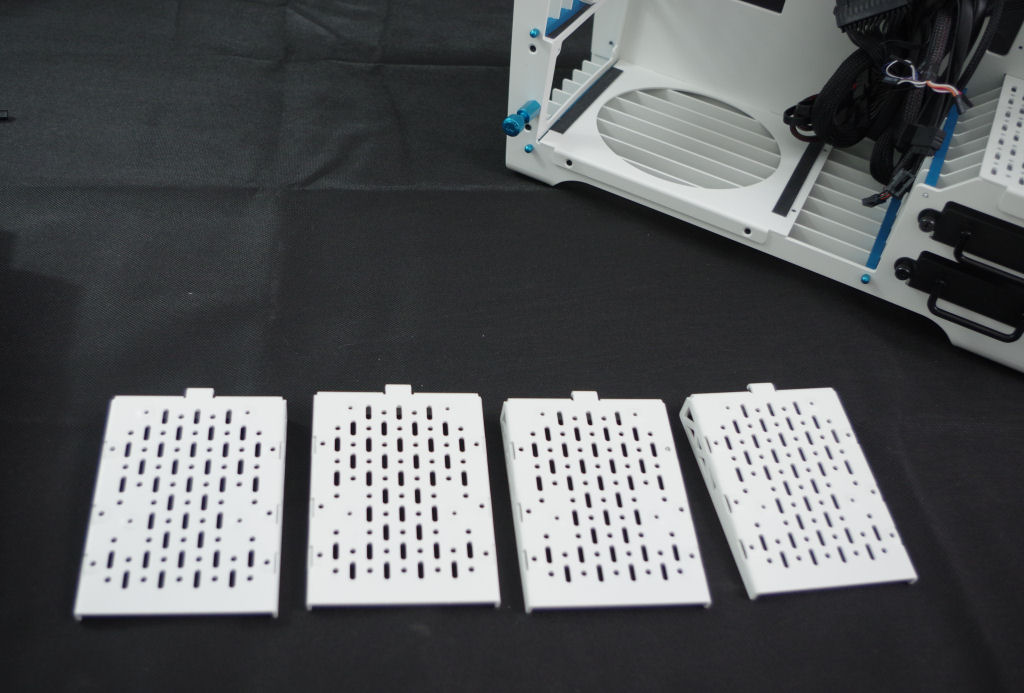

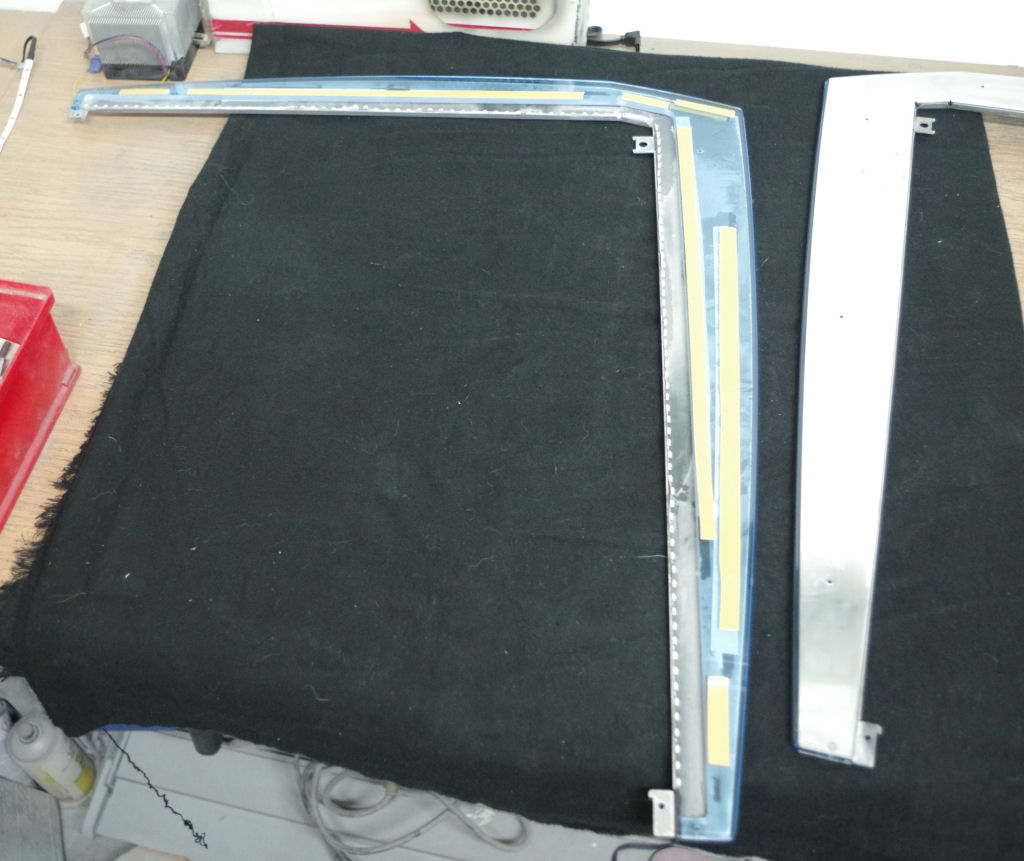

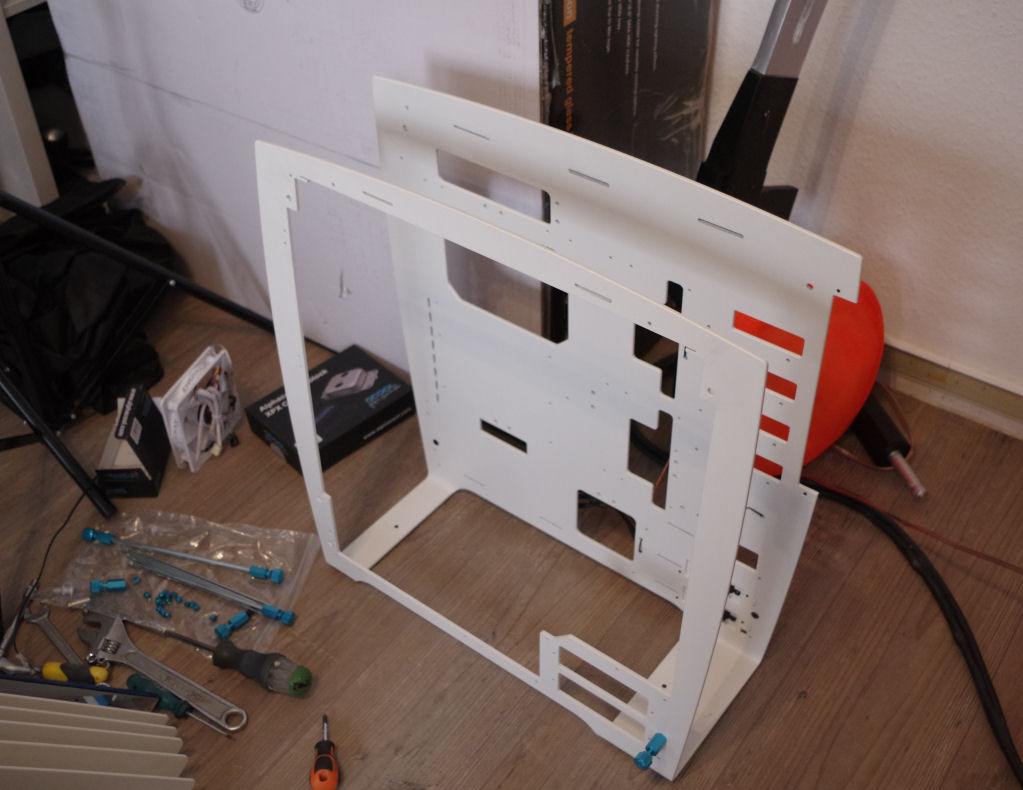

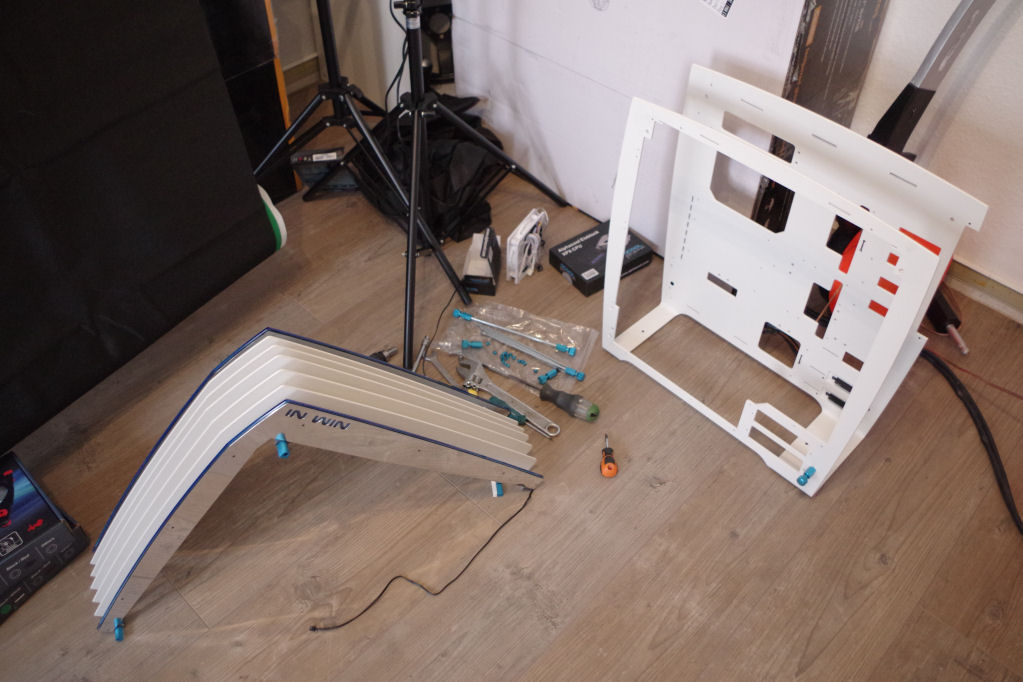

Hi everybody  We work together with Alphacool, Aquatuing & Phobya for a long time, so you can imagine , when we were asked if we could build a System for the Computex for them, we really want to create something special. So we picked an In Win H-Frame 2.0 as base for this project. Our Plans for this Project are simple but effective, so this time we won´t reshape the whole case. Instead of that we will polish a few details on the outside and add some more details on the Inside. Beside that we´re going to build a Custom Watercooling Loop with a unique Reservoir which will catch a lot of attention when its finished. This will be the base for our mod.....    Like you can imagine.....we already started the disassembling process...        As next we´re going to disassemble one of Alphacools Eisbrecher Radiator so that we can change its colors so that it matches our concept....   |

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 10 Apr 2017 at 1:19am Posted: 10 Apr 2017 at 1:19am |

|

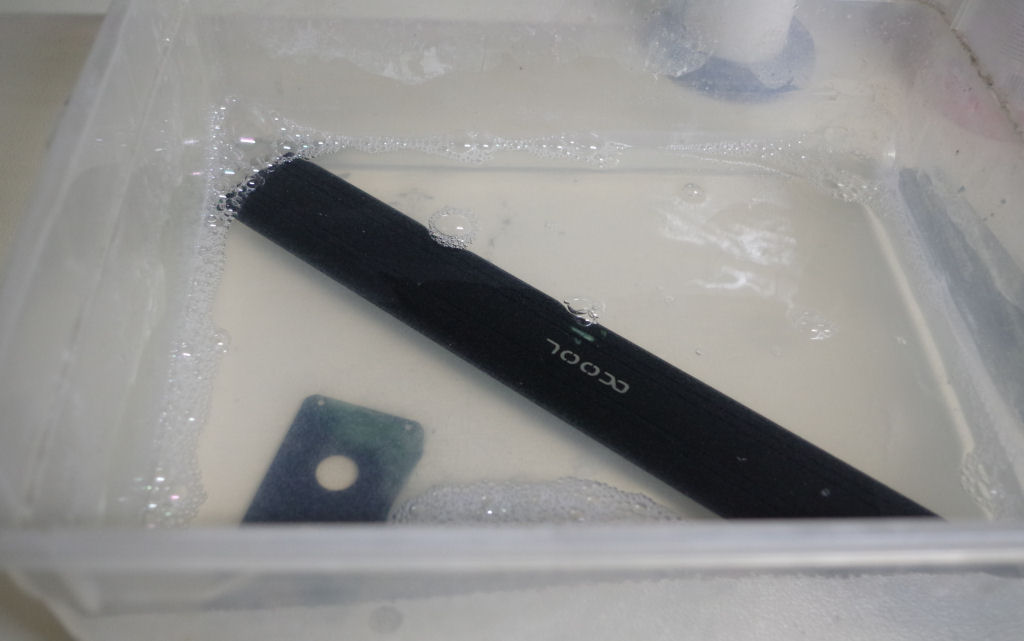

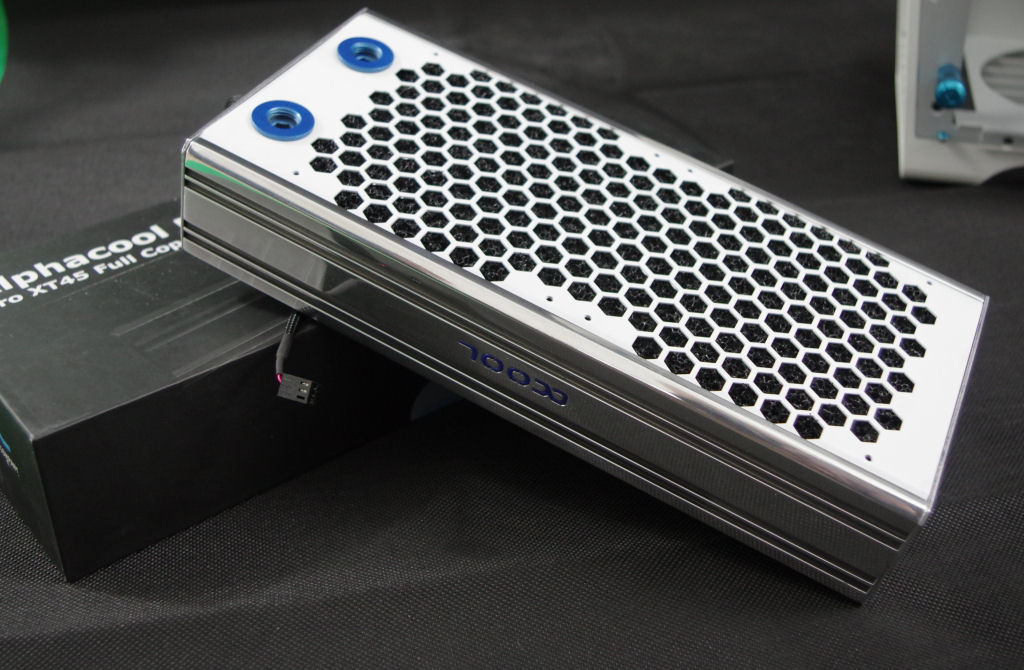

It´s time for the first update! In the last days we overworked the parts of the disassembled Eisbrecher.... First, we removed the paint from all parts. Then we polished everything until the parts were nice & shiny. At least we added a bit of paint to the Face & Bottomplate....       After that was done, we switched over to the Alphacool Eisblock XPX CPU Cooler so that we could start the same procedure on the next part...        |

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 18 Apr 2017 at 1:08am Posted: 18 Apr 2017 at 1:08am |

|

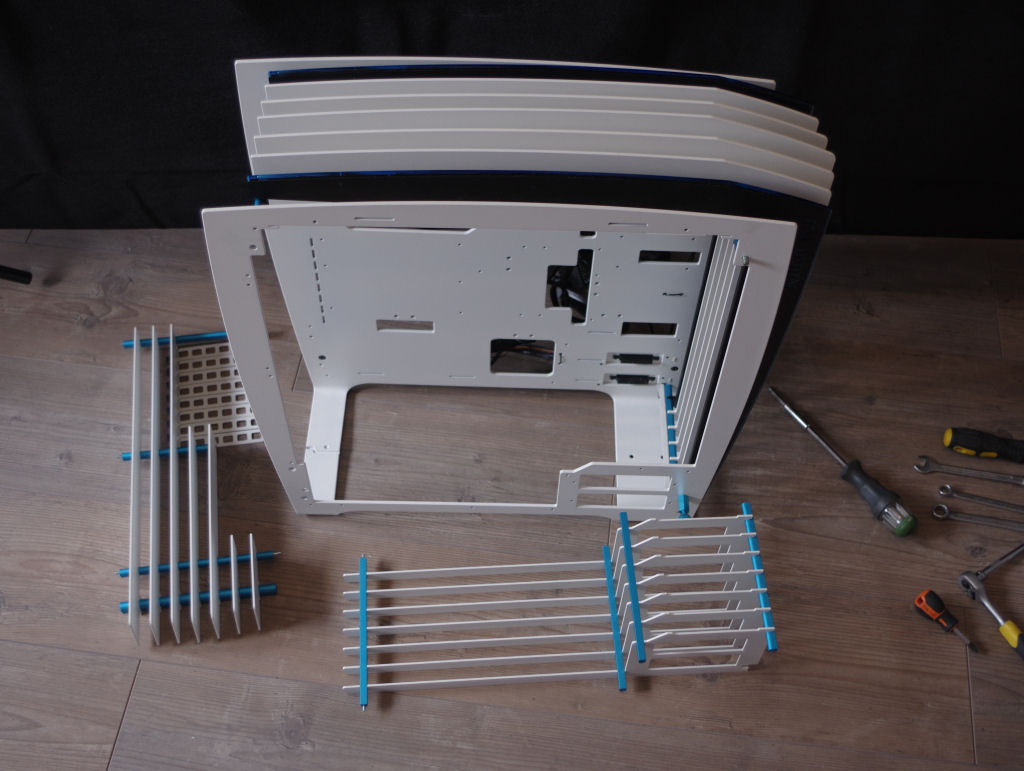

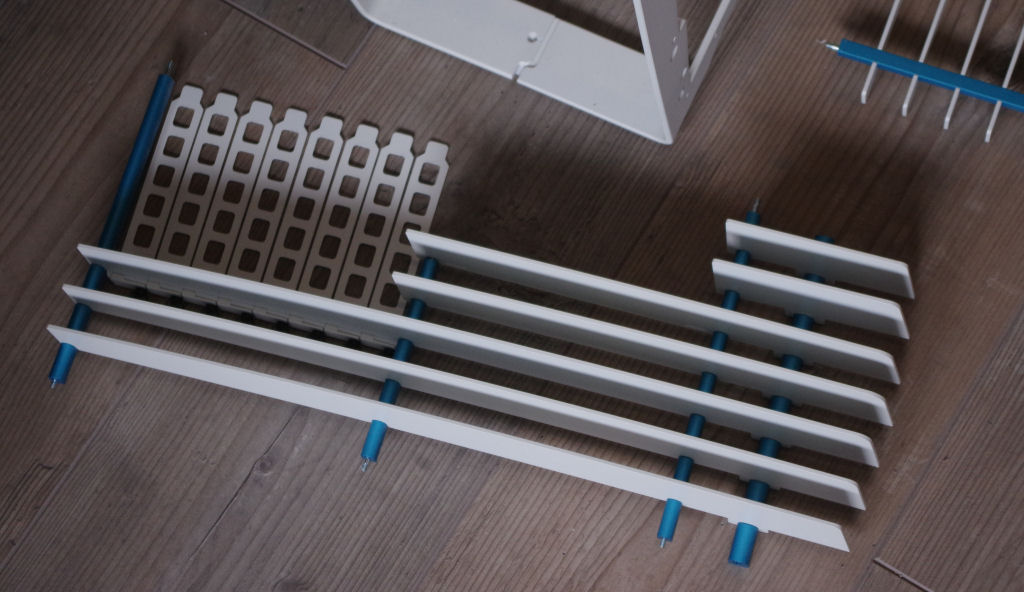

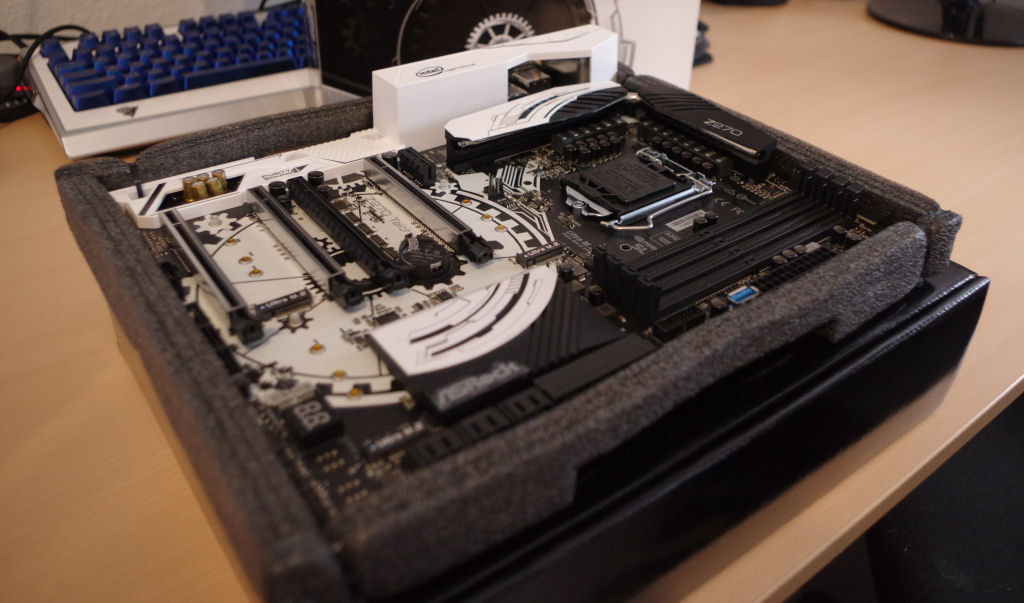

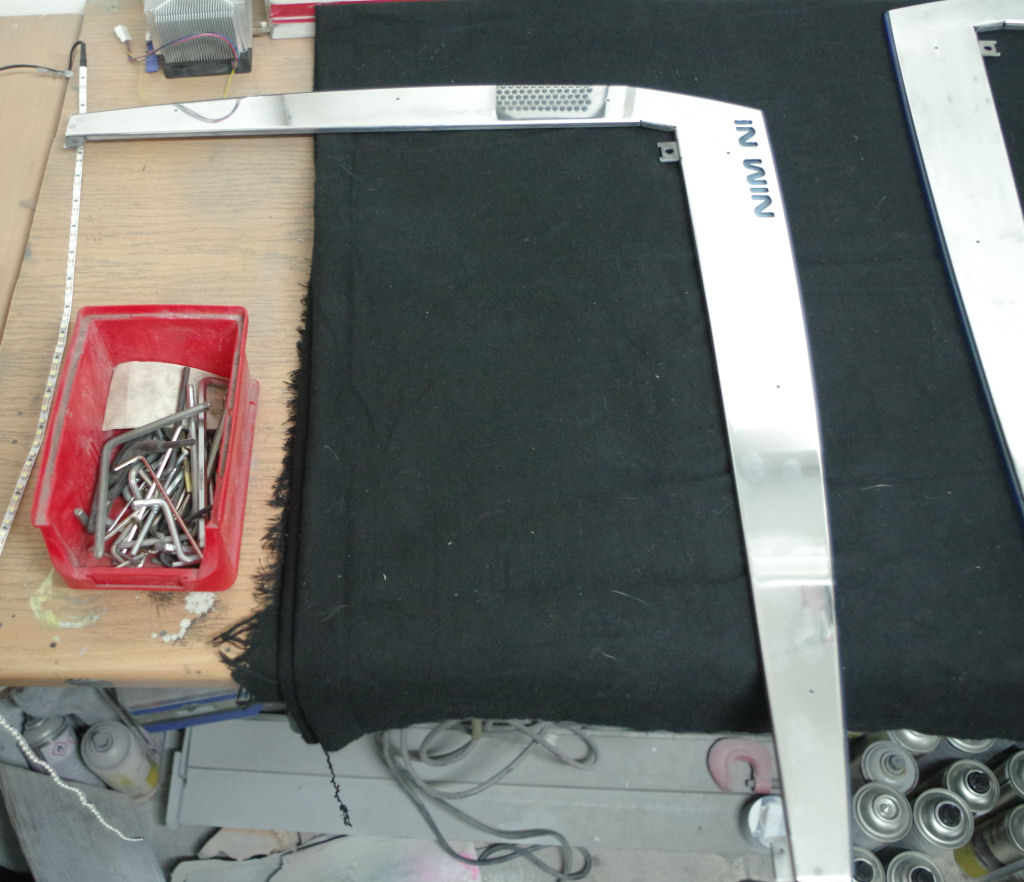

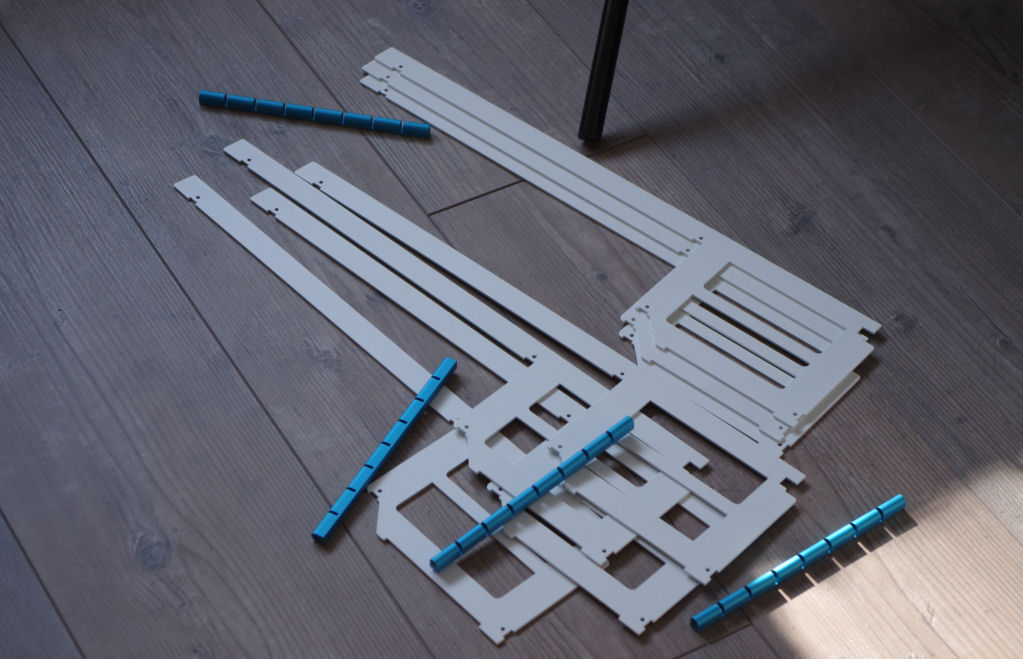

As next we took the rest of the case a bit more apart so that we could reach the both sheds with the acrylic layer inside, because we want to polish them like the radiator and the CPU Cooler...      Beside that the Fans and the mainboard for this project arrived!!! So we want to send out a big Thank you to Asrock & In Win for their Help and Support on this Project!!!!!       and we also cut out a few details which we will need later on.....  and here is a short video of the cutting process.... |

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2017 at 12:12pm Posted: 22 Apr 2017 at 12:12pm |

|

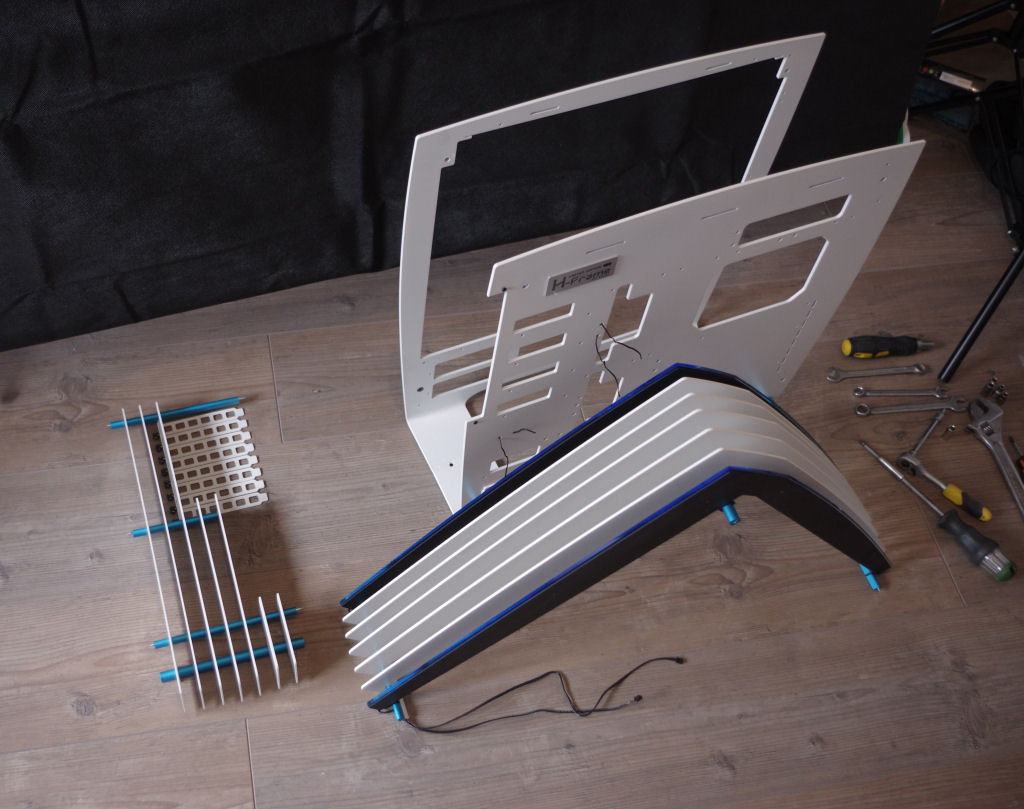

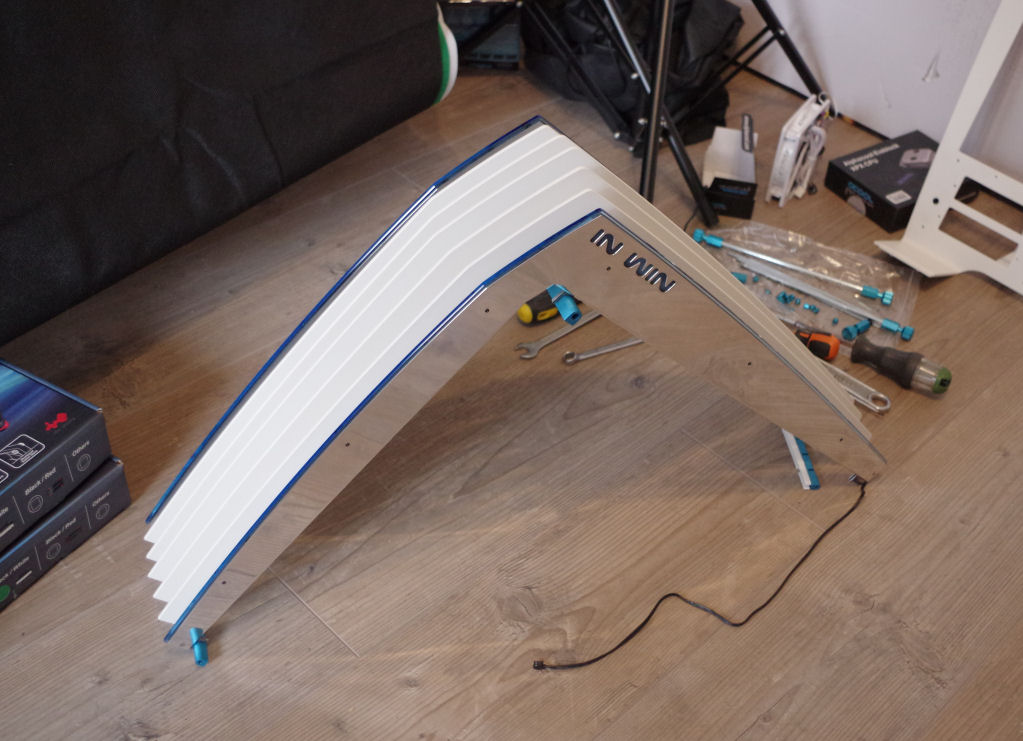

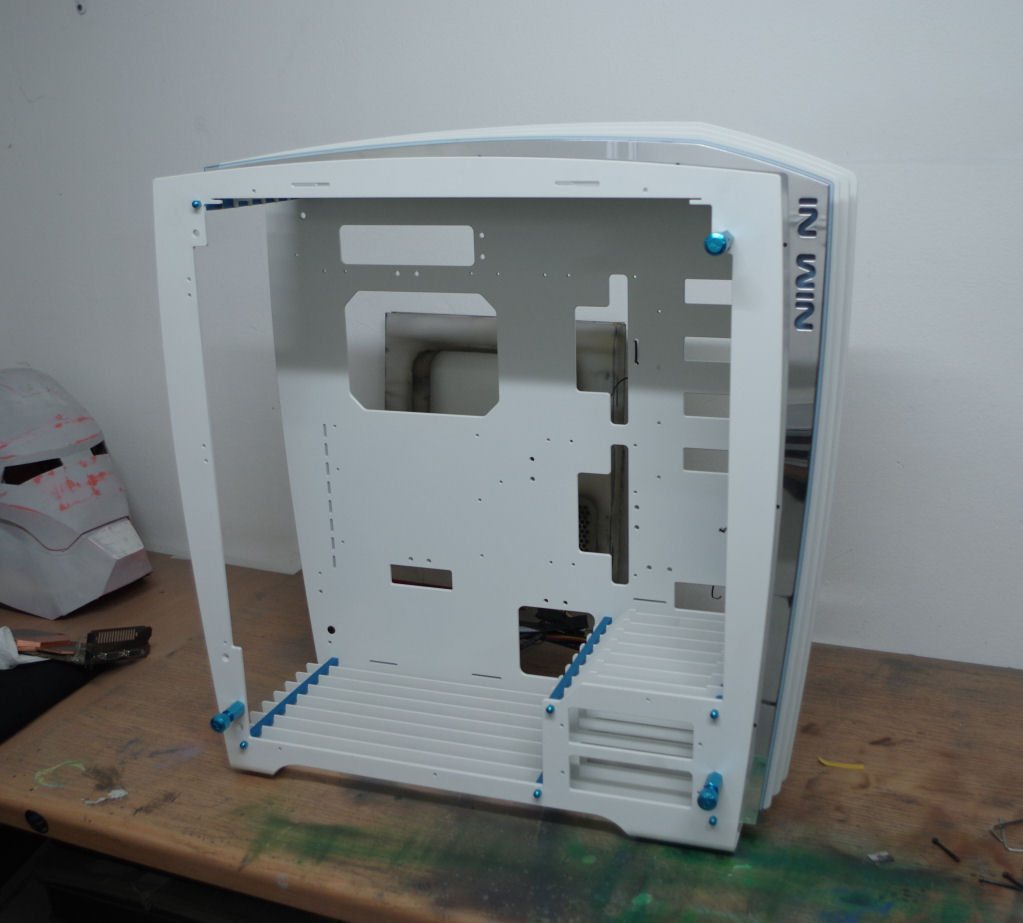

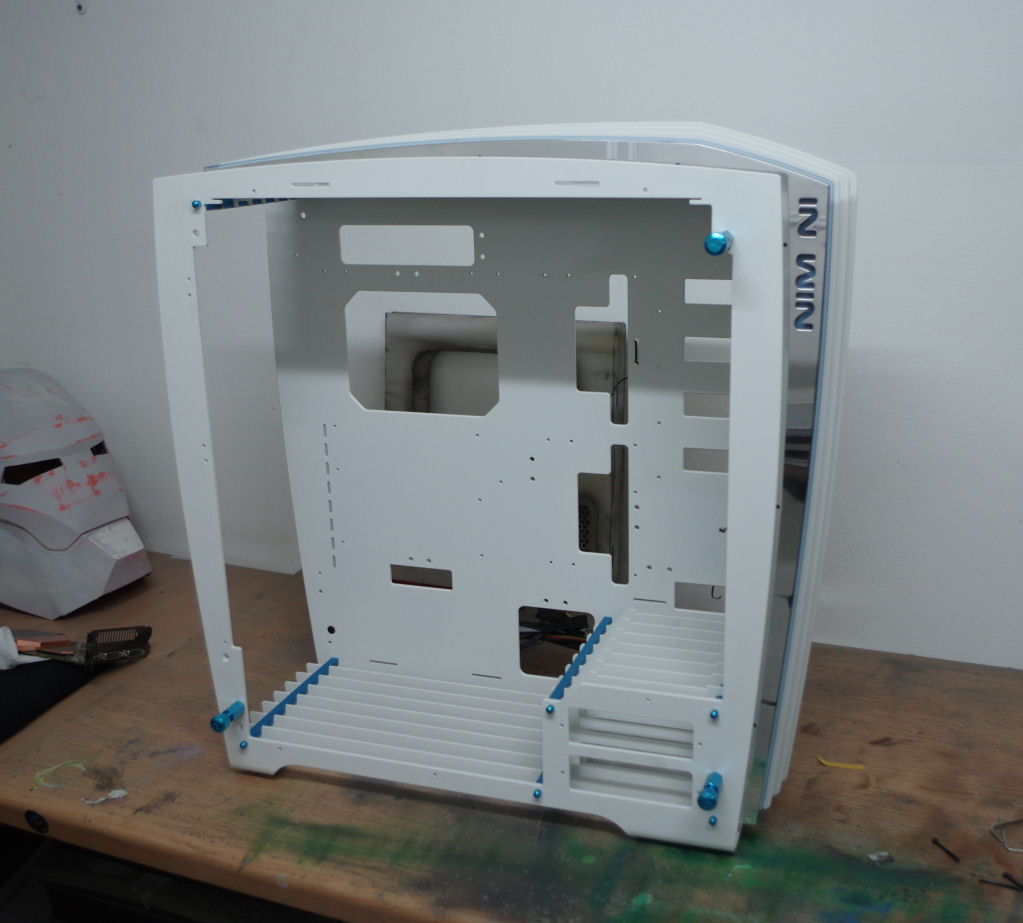

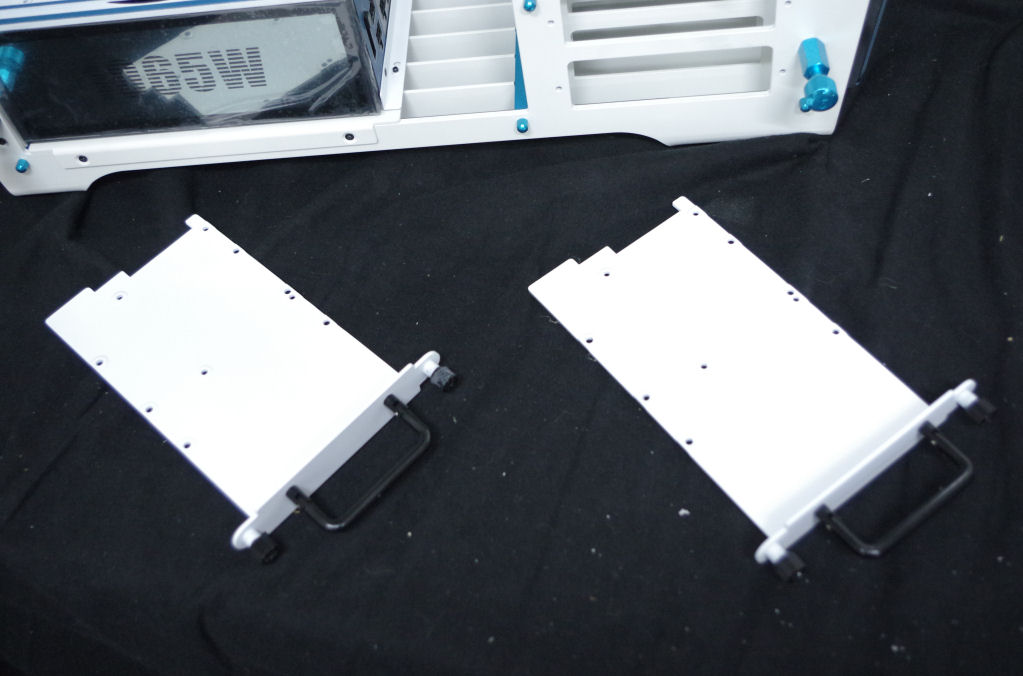

Computex is getting closer and closer....so it´s time for the next update.... In the last days we disassembled those 2 sheds with the acrylic layer inside so that we could sand/polish the outsides of both of them....after that we put everything back together so that we could continue with the next parts....           As next we´re going to start the work on the custom Reservoir which will be shaped like a half snowflake.... |

|

|

|

Xaltar

Moderator Group

Joined: 16 May 2015 Location: Europe Status: Offline Points: 32488 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 22 Apr 2017 at 2:11pm Posted: 22 Apr 2017 at 2:11pm |

|

Looking good

|

|

|

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 26 Apr 2017 at 1:08am Posted: 26 Apr 2017 at 1:08am |

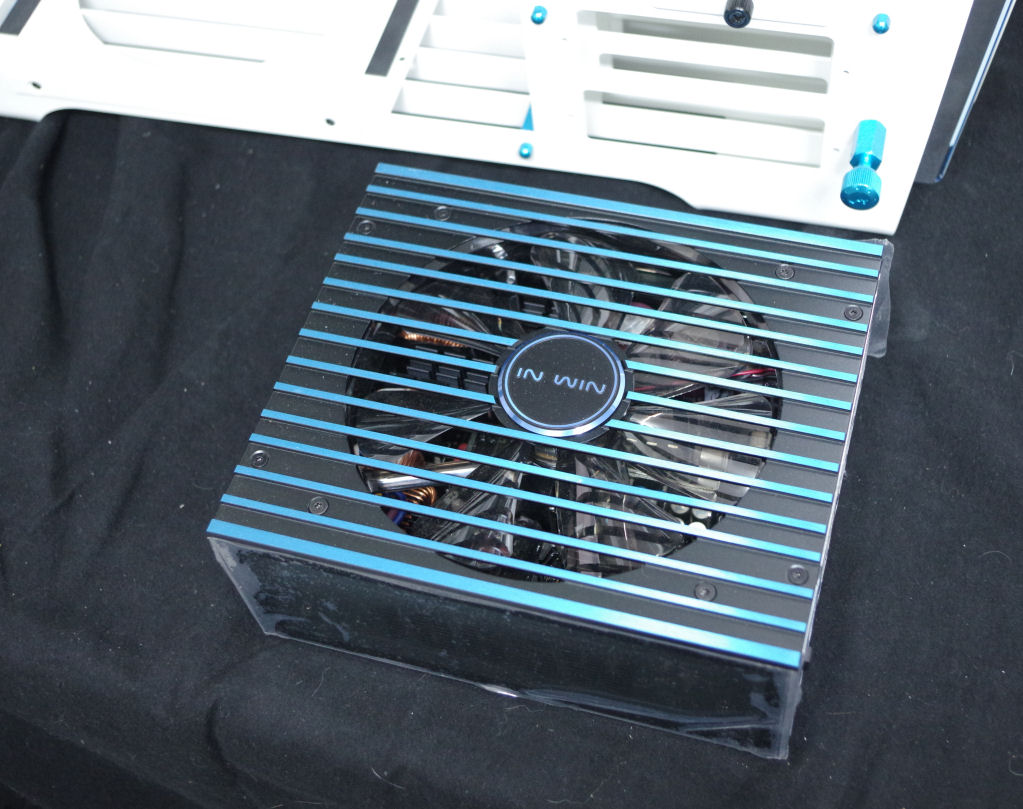

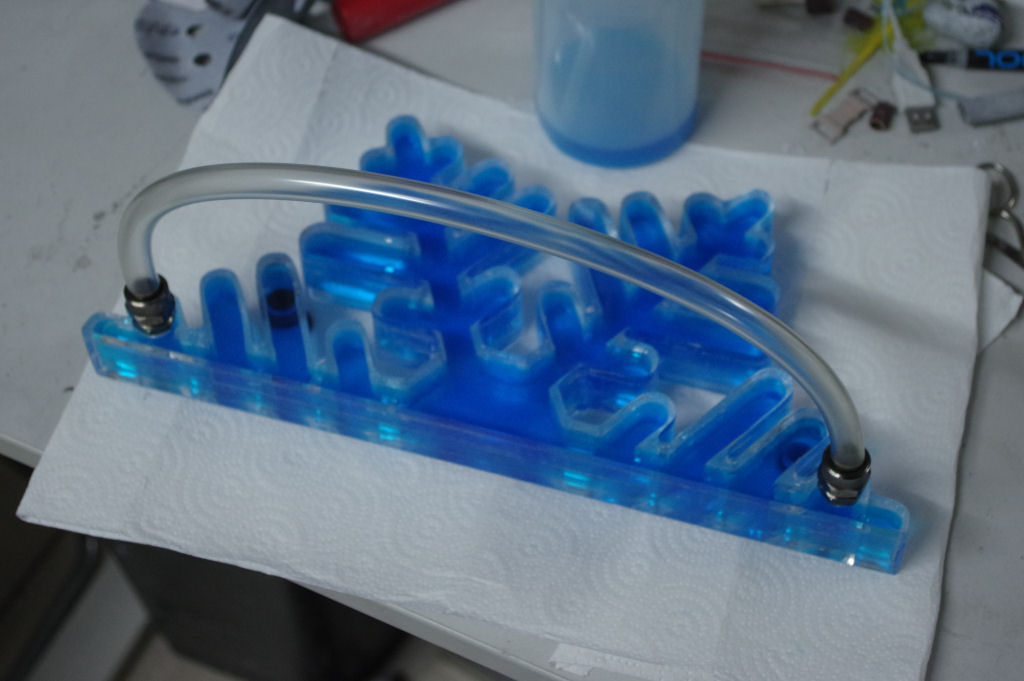

thank you!!! Like mentioned in our last Update we continued the work on this project with the reservoir for the watercooling loop.....and like mentioned it will be a custom shaped reservoir in the shape of a half snowflake. So as first step we cut out a Plexiglas Top and Bottom Layer .....   After that we cut out both middle layers with the water channels in them....  As next we mounted the mainboard & the PSU inside the Case for a first test and to have a quick look at it.....    With both parts mounted, we decided that we have to overwork the Color scheme of the PSU a little bit...so we took it out and disassembled it so that we could change the Paint on that Top Plate so that it fits our needs....     |

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 May 2017 at 12:54am Posted: 02 May 2017 at 12:54am |

|

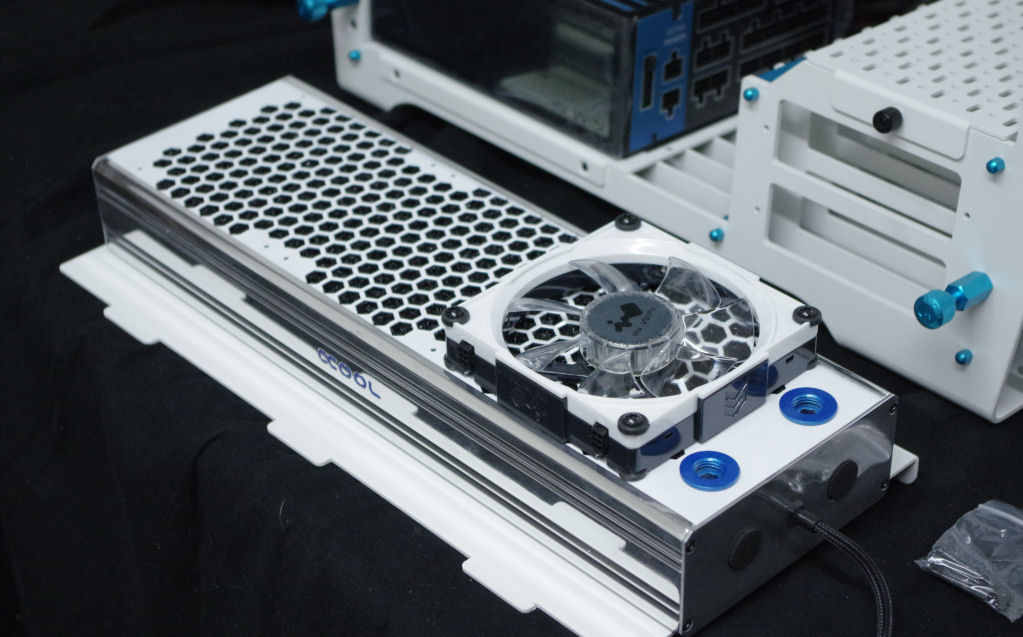

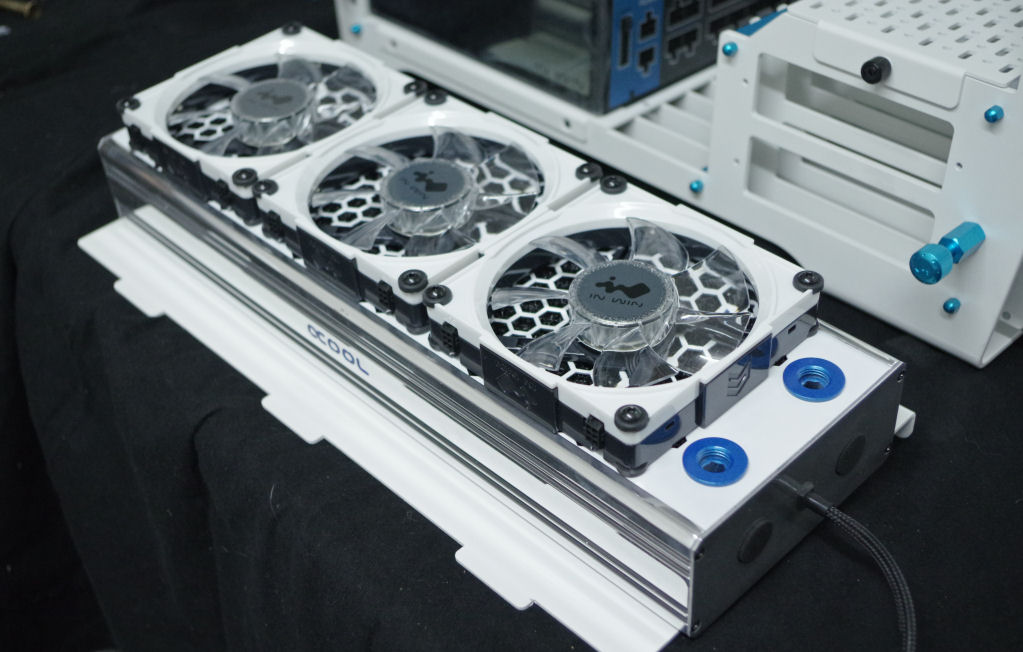

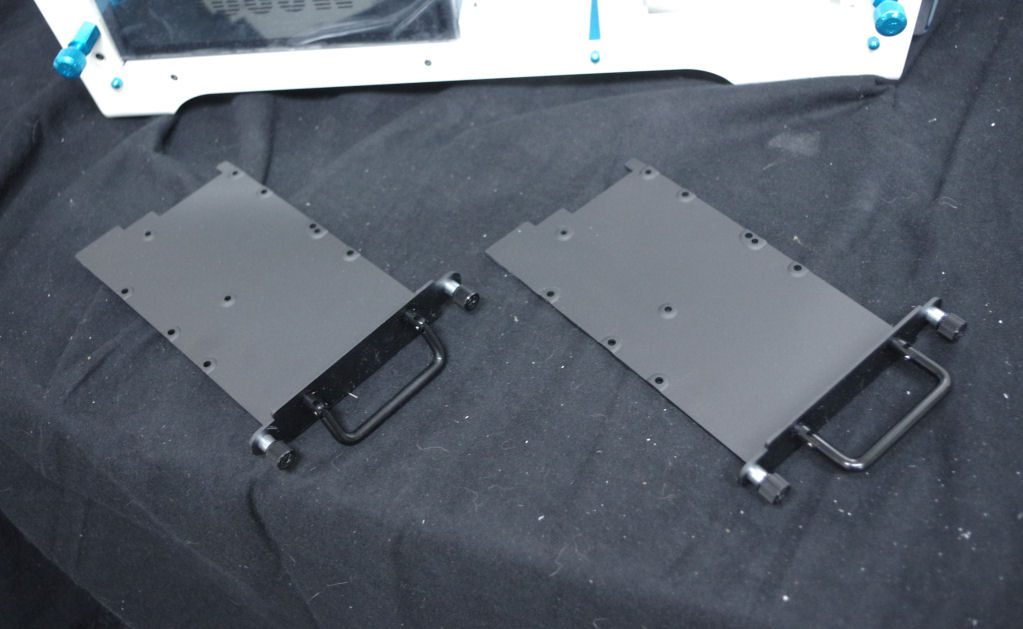

As next we mounted Radiator & Fans inside the Case so that we could take a closer look how much space will be left between the radiator & the reservoir when everything is mounted in place, just to see if we will run into problems....      Beside that we sanded and painted the HDD / SSD Holders.....   And we also continued the work on the reservoir. First we glued the 2 inner layers together so that we could overwork the inside of the waterchannels in 1 step.   After the glue was dry, we directly took a few small needle files and a cordless drill so that we could overwork the inner edge.....after that we switched from needle files to sandpaper....so that we could add the next layers as soon as possible....    |

|

|

|

Xaltar

Moderator Group

Joined: 16 May 2015 Location: Europe Status: Offline Points: 32488 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 May 2017 at 1:11am Posted: 02 May 2017 at 1:11am |

|

This is looking fantastic. I love all the little details

You know you are getting it right when the details blend in to the theme seamlessly but also pop out at you when you notice them. Looking forward to seeing this complete! Thank you for sharing

|

|

|

|

|

|

thechoozen

Newbie

Joined: 03 Apr 2017 Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2017 at 1:57am Posted: 06 May 2017 at 1:57am |

|

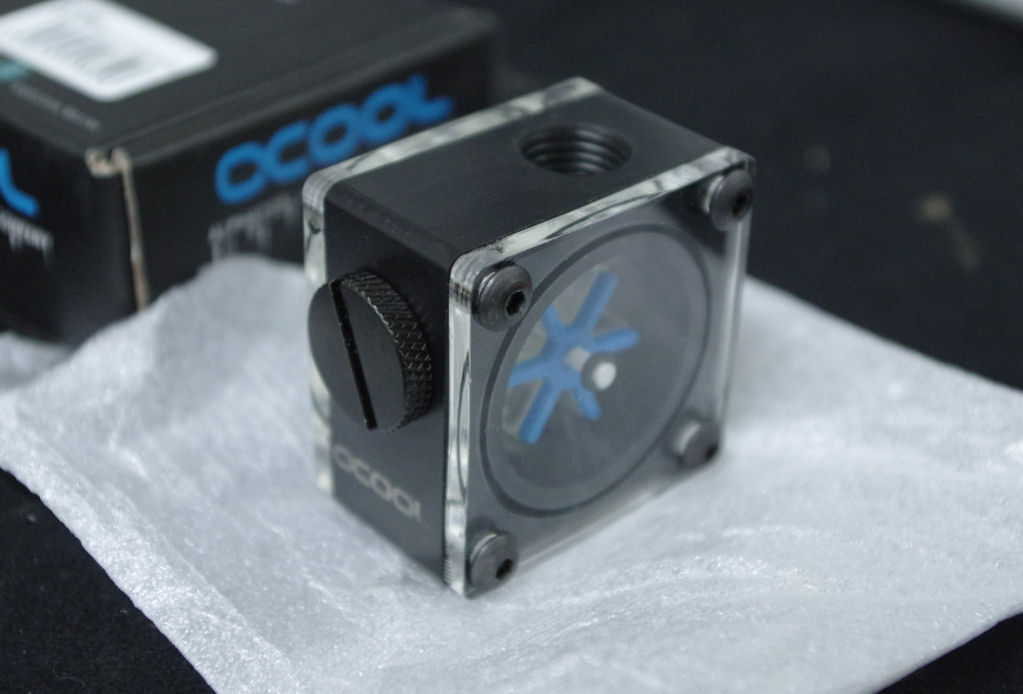

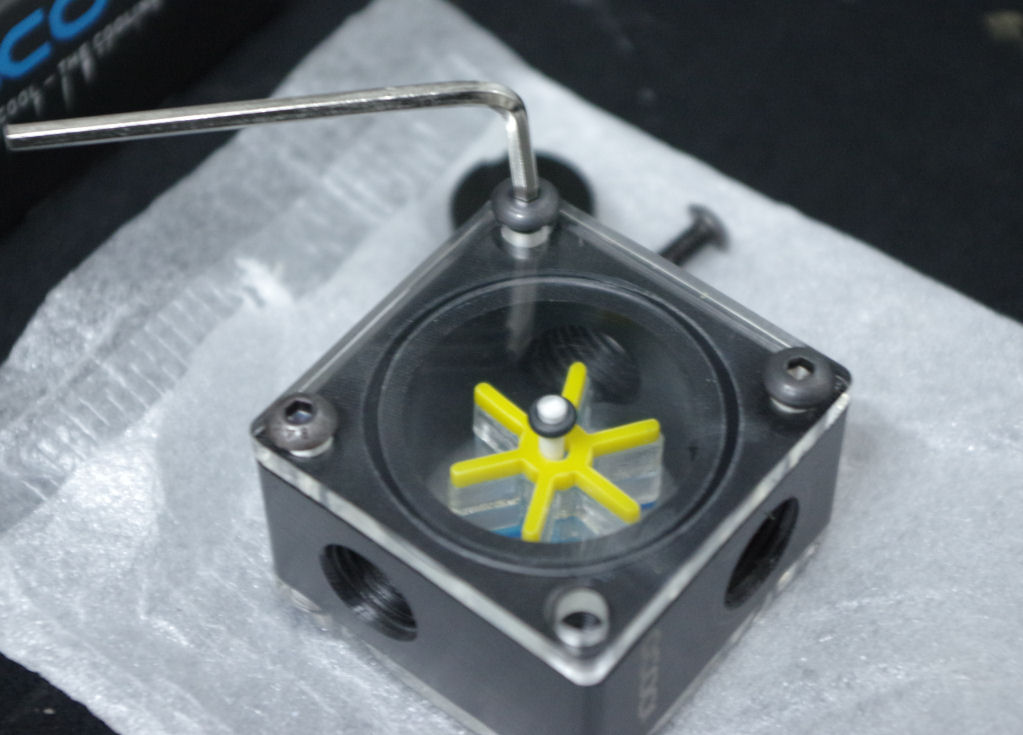

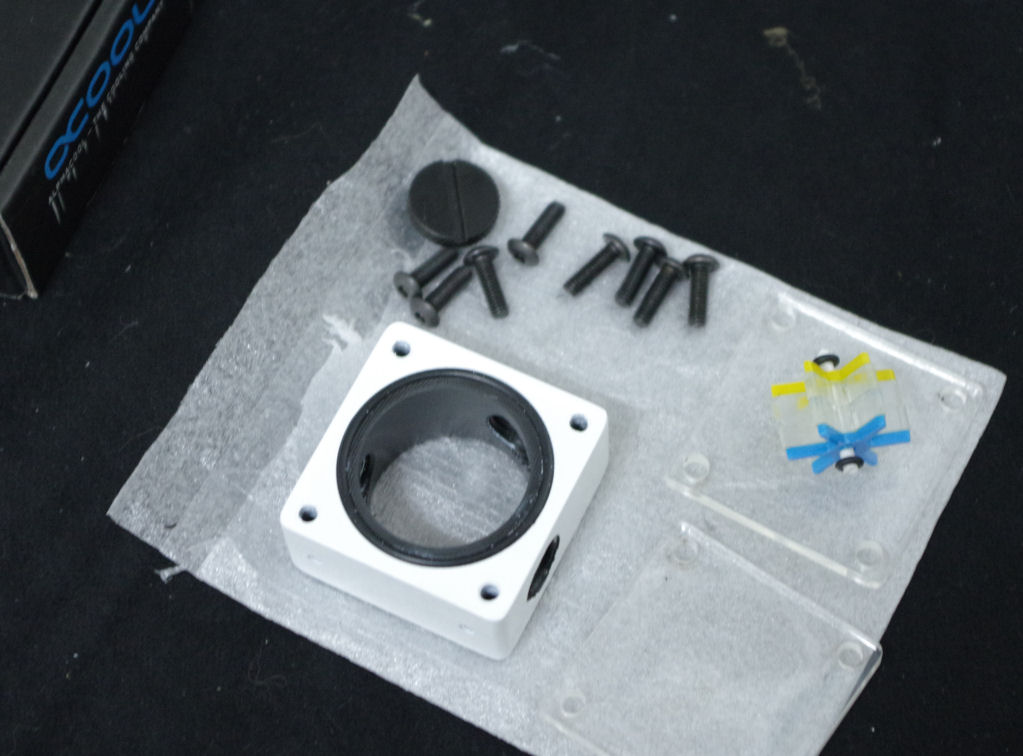

Thanks a lot Xaltar!!! It´s time for the next Update: But before we start....one of the most important Parts has arrived. So we want to send out a big Thank you to Nvidia for their Help & Support on this Project!!!!     Beside that we finished the work on the reservoir overall the sanding & polishing process took around 4-5 days but we´re happy with the result....     ....and we also prepared a flow indicator for the watercooling loop....not sure if we´re really going to use it....but it´s good to be prepared.....       |

|

|

|

Xaltar

Moderator Group

Joined: 16 May 2015 Location: Europe Status: Offline Points: 32488 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 06 May 2017 at 2:43am Posted: 06 May 2017 at 2:43am |

|

That reservoir is insane! Amazing work

|

|

|

|

|

|

Post Reply

|

Page 12> |

|

Tweet

|

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |